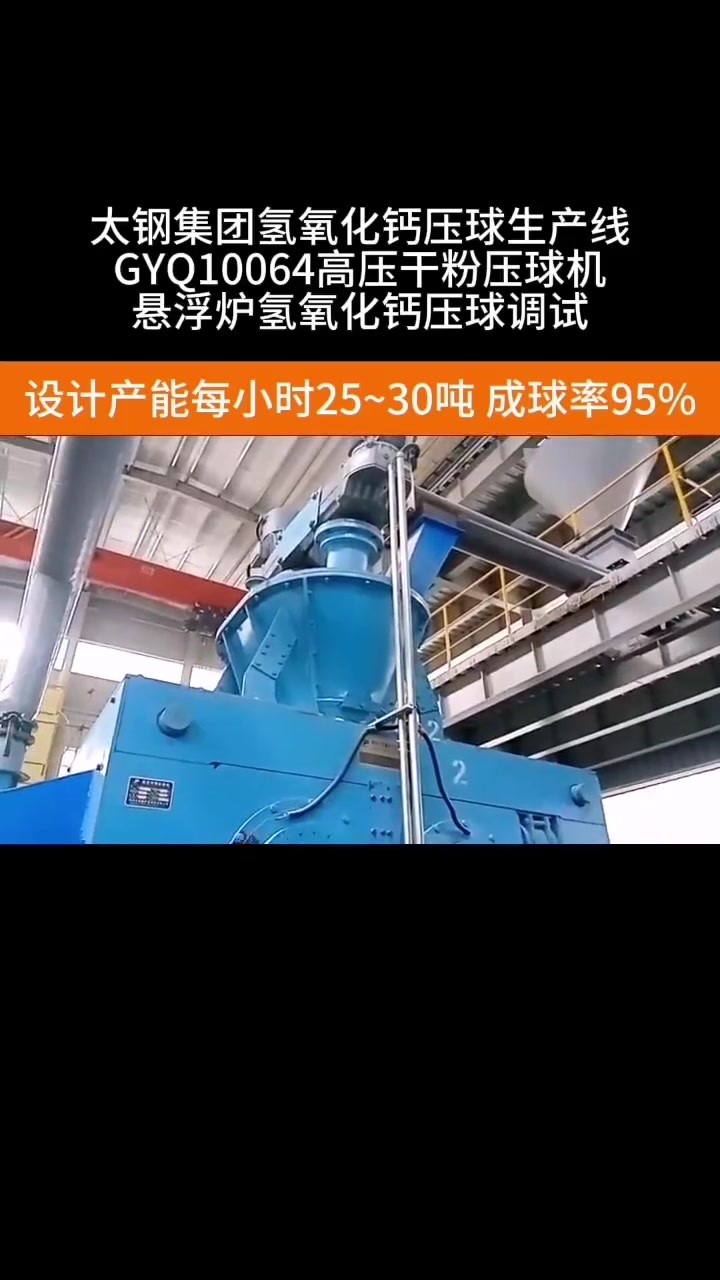

Taiyuan Steel Plant's annual production line for pressing 400,000 tons of metallurgical additives (calcium hydroxide pellets)

Ball Press Machine Configuration

| Ball Press Machine Model | GYQ10064 | GYQ10035 | GYQ8535 |

| Pressure roller diameter (mm) | 1000 | 1000 | 850 |

| Roller skin width (mm) | 640 | 350 | 500 |

| Design capacity (t/h) | 25-30 | 20-25 | 12-15 |

| Main motor power (kW) | 315 | 315 | 250 |

| Pre-compressed motor power (kW) | 37x2 | 45 | 30 |

| Maximum cylinder thrust (t) | 1200 | 1100 | 740 |

| Maximum roll skin line pressure (t/cm) | 20 | 28 | 21 |

| Total Pressure (T) | 1000 | 1000 | 1000 |

| Complete machine (length × width × height) (mm) | 5500 * 5300 * 5200 | 7200 x 4900 x 5200 | 5300 x 4600 x 5000 |

| Total machine weight (T) | 75 | 73 | 47 |

*Note: Production output may vary depending on factors such as material type and feed particle size. Technical specifications are subject to change without prior notice. Please refer to the actual equipment for weight and overall dimensions.

|

|

|

Highlighting strengths

The GYQ series ultra-high-pressure pelletizing machine is one of the leading pelletizing devices in the industry—known for its high sales volume, large production capacity, and exceptional efficiency. Hongxin’s ultra-high-pressure pelletizer is specifically designed to compress ultra-fine powders into uniform pellets, capable of turning 80- to 500-mesh powders directly into spherical shapes in a single step. It is widely used in large-scale pelletizing production lines.

01

Ultra-High-Pressure Ball Press Roller Assembly

02

Strong load-bearing capacity, high stability

03

Enhance the mandatory feeding system

04

Simple structure, easy to maintain

05

Centralized Lubrication System, Easy to Maintain

06

Low noise, minimal dust

How it works

Related videos

Calcium Hydroxide Ultra-High-Pressure Pellet Machine 1

Calcium Hydroxide Ultra-High-Pressure Pellet Machine 2

Calcium Hydroxide Ultra-High-Pressure Pellet Machine 3

Get a quote

Leave us your contact information and receive a free product quote.

We provide professional briquetting machine equipment and competitive quotes.

We will contact you within 24 hours of receiving your message.

Tel:+86-13703990669

Tel:+86-18182214485

Email:sales@hongxinmining.com

Address: Longgang Development Zone, Xingyang City, Zhengzhou City, Henan Province

Email:zzhxjixie@126.com

Tel:+86-13703990669

Tel:+86-371-64696918

Address: Longgang Development Zone, Xingyang City, Zhengzhou City, Henan Province

Leave a Message

The need for specialized plant growth regulators